Overview

As two main capacitor types, film and aluminum electrolytic capacitors play different complementary roles in electronic industry. This article systematically analyzes the significant differences in their application areas, focusing on their structural principles and performance characteristics. It also dig into the underlying factors that drive these differences, including fundamental differences in dielectric materials, electrode structures, and operating mechanisms. Based on the advantages of film capacitors in high-temperature stability, high-frequency characteristics, and long life, and the advantages of aluminum electrolytic capacitors in high capacitance and low cost, this article further explores the development opportunities and challenges of these two types of capacitors in the future electronics market, providing theoretical guidance and practical reference for electronic engineers.

1.Comparison of Basic Characteristics of Film and Aluminum Electrolytic Capacitors

The fundamental differences between film and aluminum electrolytic capacitors stem from their distinct structural designs and material systems. Film capacitors use a polymer film (such as polypropylene or polyester) as the dielectric material. Metallized electrodes are formed on the film surface through a vacuum evaporation process, resulting in extremely low dielectric loss and excellent frequency characteristics. In contrast, aluminum electrolytic capacitors use aluminum oxide as the dielectric layer and rely on an electrolyte to provide a conductive path to the cathode. While they achieve higher volumetric capacitance, they suffer from significant equivalent series resistance (ESR) and leakage current issues. Film capacitors offer significantly better temperature stability than aluminum electrolytic capacitors, operating stably across a wide temperature range of -40°C to +105°C and even higher, whereas aluminum electrolytic capacitors’ performance can vary significantly with temperature fluctuations. Film capacitors typically last over 15 years with little concern for aging. In contrast, the service life of aluminum electrolytic capacitors is limited by electrolyte depletion, typically around 2,000-8,000 hours. These fundamental differences determine the distinct roles that film and aluminum electrolytic capacitors play in electronic industry.

2.Typical Application Differences Between Film and Aluminum Electrolytic Capacitors

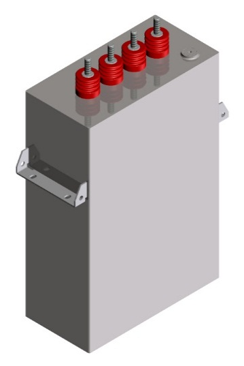

Film capacitors and aluminum electrolytic capacitors have established a clear division in practical applications, each occupying distinct market segments. Film capacitors, due to their excellent high-frequency characteristics and low loss, are primarily used in high-frequency filtering, resonant circuits, pulse applications, and electronics control. These applications include DC-link capacitors in inverters and X2 safety capacitors for switching power supplies. In contrast, aluminum electrolytic capacitors, due to their high capacitance density and cost-effectiveness, dominate low-frequency filtering and energy storage applications, such as power input/output filtering and audio coupling. In new energy vehicles, film capacitors are widely used in motor drive systems due to their high-temperature resistance and long life, while aluminum electrolytic capacitors are more commonly used in low-voltage power systems. In industrial control, film capacitors are the preferred choice for inverters and servo drive systems, while aluminum electrolytic capacitors are commonly found in PLCs and general power modules. This application differentiation reflects the irreplaceable nature of film capacitors in high-performance, high-reliability applications, and the economic advantages of aluminum electrolytic capacitors in cost-sensitive applications.

3.Analysis of the Deeper Technical Reasons Behind the Differences in Applications

The divergence in the application areas of film and aluminum electrolytic capacitors stems from fundamental differences in their material systems and manufacturing processes. Film capacitors utilize a highly pure polymer film as their dielectric material with stable molecular structure and extremely low polarization losses. This allows them to maintain excellent performance even at high frequencies. In contrast, aluminum electrolytic capacitors rely on a combined aluminum oxide dielectric layer and electrolyte, limiting their high-frequency performance due to their ionic conduction mechanism. The metallized electrodes of film capacitors are formed through vacuum evaporation, enabling precise thickness control and low contact resistance. However, the cathodes of aluminum electrolytic capacitors utilize a composite structure of electrolyte and conductive material, resulting in high contact resistance.The self-healing properties of film capacitors allow them to withstand transient overvoltages without permanent damage, whereas aluminum electrolytic capacitors are susceptible to dielectric breakdown after overvoltage. These differences in technical characteristics fundamentally determine the respective suitable applications for film and aluminum electrolytic capacitors.

4.Future Development Trends and Market Prospects of Film and Aluminum Electrolytic Capacitors

As electronic technology evolves toward higher frequencies and higher reliability, film and aluminum electrolytic capacitors will face distinct market opportunities and challenges. Film capacitors are expected to gain wider application in new emerging market such as new energy vehicles, renewable energy, and 5G communications. Their advantages will be particularly evident in electric vehicles operating at high voltages of 800V and above. Aluminum electrolytic capacitors face competition from new technologies, but they will maintain their importance in consumer electronics and general industrial power supplies. From a technological perspective, film capacitors are moving toward higher temperature ratings (above 125°C), lower ESR, and smaller sizes. Continued innovation in metallized polypropylene film technology will push the boundaries of performance. Aluminum electrolytic capacitors are focusing on improving high-frequency characteristics and extending service life. Market data predicts that the global film capacitor market will grow at an average annual rate of 6-8%, faster than the 3-5% growth rate for aluminum electrolytic capacitors, reflecting the electronics industry’s continued demand for high-performance capacitors. However, the two types of capacitors will continue to coexist for a long time, each playing an irreplaceable role in its respective applications.

Conclusion

The differences in the application of film and aluminum electrolytic capacitors reflect the fundamental principle of “the right one is the best” in the electronic component industry; there is no absolute superiority or inferiority. The analysis in this article clearly demonstrates that film capacitors with their superior high-frequency characteristics, temperature stability, and long life, hold a unique position in high-performance electronic systems. Meanwhile, aluminum electrolytic capacitors, with their high capacitance density and cost-effectiveness, maintain a competitive advantage in high-capacity applications. Future developments in electronic devices will drive technological advancements for both types of capacitors. Film capacitors are expected to expand their market share in high-end applications, while improved aluminum electrolytic capacitors will remain competitive in traditional applications.